Why Spring-Ride?

Here are a few things you may not know about trailer suspensions.

The type of suspension on your semi-trailer has an impact on your bottom line. It can affect the safety of your shipments, your fleet utilization, your driver’s job satisfaction and the long-term profitability of your business.

But maybe not in the way you’re thinking.

A trend began in trucking about 20 years ago with the advent of air-ride suspension—first on tractors, then on trailers. XTRA Lease took part, building a large fleet of trailers with air-ride suspension.

But the spring-rides never went away. The simple spring-ride suspension has met the demands of trucking for many decades. And for good reason. It gets the job done well with less maintenance and lower cost than air-ride suspension.

When it comes to trailer technology, spring-ride suspension is a commonsense choice. It costs less to maintain over its lifecycle and spring-ride fits multiple applications.

That said, not every product can or should be hauled in a trailer with spring-ride suspension—some easily bruised produce, for example. But the versatile, simple, and proven spring-ride trailer usually fills the bill.

What's going on with suspension types?

There’s been a tidal wave of air-ride suspensions over the last two decades. The main reason? Shippers or brokerages asked for it. They thought the only way to guarantee a safe shipment was to have it hauled on an air-ride suspension. So every trucking company that wanted to stay in business was compelled to spec air-ride.

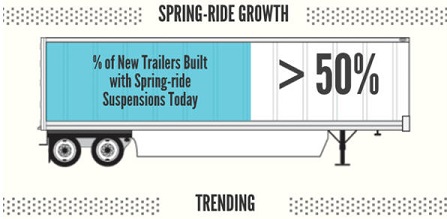

Today, more than 50% of dry vans built have spring-ride suspension. And they’re not sitting around empty; they’re moving freight.

What changed?

These days there’s less potential for cargo damage. Product packaging has improved. Cargo can be better secured in van trailers. And shippers have improved the configuration of pallets and are optimizing the way cargo is packaged and loaded to get optimal use from trailers.

Driver retention now is influenced more by pay, technology and length of haul than by the suspension on the trailer they pull. Long-haul trucking is a difficult job. Many years ago, drivers had to do a lot of bobtailing, and EMPTY spring-ride trailers bounce around. To retain drivers, trucking companies tried to give them a nice, smooth ride by putting air-ride suspension on tractors and trailers.

Today, few miles are driven empty and the comfort of new cabs and more cargo-appropriate types of trailer doors have made the driver’s job easier. The type of suspension on the trailer is a second thought.

Shippers have been on board with spring-ride for many years. With the boom in international containerization and in putting domestic shipments in intermodal containers—all of which travel on spring-ride suspensions—spring-ride technology has built a strong track record.

So why spring-ride?

Think about this: if freight can cross an ocean, then bounce around on railroad tracks for hundreds of miles, what difference could air-ride suspension make on the last few miles of the trip?

- You may also like our post Comparing Maintenance and Costs of Trailer Suspensions.

- Read our white paper comparing spring-ride and air-ride suspensions.

- Schneider has some real-world test results you may like to see.

- Check out Schneider’s white paper comparing spring-ride and air-ride suspensions.

- See our infographic comparing spring-ride and air-ride suspensions.

- A&M Carriers finds no effect on driver retention with increase in spring-ride suspensions.