How Tires Inflate Your Costs

How Much Your Truck's Tires May Be Costing You Each Mile

When the Obvious Isn't Always Obvious

We all understand tires, right?

We're transportation professionals. We eat, drink, and breathe logistic excellence. So, we all know that the most important part on any truck or trailer on the road isn't the new hybrid assist powertrain or your new TMS platform tracking system, it's the tires. Your fleet can invest in all the technology and equipment in the world to increase efficiency, but without 18 pieces of rubber touching the road, your load isn't going anywhere.

Despite how important tires are in getting loads from Point A to Point B, a remarkable number of trucks on the road are driving on poorly inflated tires. According to the North American Center for Freight Efficiency:

| TRACTOR | TRAILER |

|---|---|

| About one in five tractors are operating with one or more tires underinflated by at least 20 psi. | About one in five trailers operate with one or more tires underinflated by at least 20 psi. |

| More than 3% of all tractors/trucks are operating with at least one tire underinflated by 50 psi or more. | Approximately 3% of all trailers are operating with at least one tire underinflated by 50 psi or more. |

| Only 46% of all tractor tires inspected were within +/- 5 psi of the target pressure. | Only 38% of all trailer tires inspected were within +/- 5 psi of the target pressure. |

| Nearly 3.5% of all tractors/trucks operate with four or more tires underinflated by at least 20 psi. | 3% operate with four or more tires underinflated by at least 20 psi. |

Well, that's not great, but what's the real impact?

Mis-inflated Tires Cost You Money

Like any specialty tool or part, tires work best under specific conditions. Use your tool outside of those conditions, you can greatly reduce its lifespan or effectiveness. For example, most rechargeable batteries have an expected cycle count (the # of times they can be charged) before they need to be replaced. However, leaving batteries in extreme heat or cold can affect the battery's ability to take and hold a charge or cause catastrophic failure like overheating or shorting out. A tire is no different.

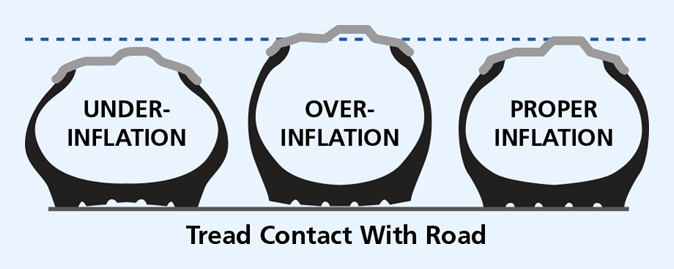

Proper tire inflation means the tire tread contacts the road surface evenly, maintaining consistent wear and distributing the weight of the vehicle equally across the surface of the tire's contact point. Properly inflated tires provide stable, consistent performance and better fuel mileage. However, under- or over-inflation can drastically reduce the tire's performance — in real-time and over the tire's life.

When a tire is underinflated, the center of the tread takes less wear while putting more weight, strain, and wear on the outside of the tread. This results in more heat, the number #1 enemy of tires. Heat affects the tire's rolling resistance which leads to reduced fuel economy. Excess heat can also lead to structural issues that can make retreading a tire impossible.

Overinflation causes the opposite effect. The center of the tire is required to take the entire weight of the load as the outside of the tread no longer makes contact with the road. This creates irregular wear patterns characterized by center rib wear or rib punch wear. This irregular wear makes the tire more susceptible to road hazards such as impact breaks.

All of this means that your tires wear out faster. How much faster?

The answer depends on who you ask.

| Yokahama | Michelin / Goodyear | Schrader-Bridgeport | Retread Industry Report |

|---|---|---|---|

| "20% underinflation can reduce tire life 30%." | "More than 14.5 psi underinflation will cause rapid deterioration in use with reduced stability and grip. Reduction in longevity." | "Just 5 psi below placard pressure could lessen a tire's tread life by as much as 25%." | A 20% under-inflated tire will, over the life of the casing, reduce the effective life of that casing by 30%. |

| "30% underinflation can reduce tire life 40%." | "Underinflation can cause poor handling, fast and/or irregular wear, decreased fuel economy and permanent structural damage" | "30% underinflation Results in a 55% tire life penalty" |

Assuming an expected tire life of 100,000 miles, 20% underinflation could yield 30,000-50,000 fewer miles per tire. Even using a generously low average tire price of $400/tire, assuming 50,000 miles per year driven, underinflation could cost you up to an extra $200 per tire a year.

That's just the physical tire cost. More than likely, chronically underinflated tires will cause larger problems like flats or blowouts. Add emergency road service into the cost of replacing your tire, not to mention the time and opportunity cost of lost productivity, and an underinflated tire becomes a serious cost center.

According to Robert Palmer, director of market sales engineering at Bridgestone Americas, "Tires never forget. [Tires] basically are a cumulative effect of what's happened to them — poor inflation pressure, maintenance, running low, curbing, or impacting, or running over an object." What a tire experiences over its lifetime directly impacts its service longevity.

Underinflation could cost you a retread

Underinflation is a major contributor to premature tire removals or tire failure. However, underinflated tires can also reduce or eliminate the ability to retread used tires.

As we've already seen, underinflation of a tire causes extra heat buildup in the tire. When a tire runs under-inflated, it can begin to generate increasing temps, which can impact the wheel, tire, and wheel end area. The tire effectively can become like an oven that bakes that area and that wheel end on which it's mounted. Just as time ages people, heat ages tires. This can cause cracking, flexing, and even separation of the tread from the casing.

So, underinflation not only costs you the effectiveness of the tires but also increases the cost. Retreads can often cost a fraction of the cost of new tires with similar expectations for performance and longevity. With high-quality tires often offering a warranty through multiple retreads, damaging a quality casing could cost you hundreds in possible retread savings.

What about duals?

Tires in a dual capacity should match in diameter. If they don't, the smaller tire is dragged along by the larger, resulting in rapid and irregular wear on the smaller tire.

Different inflation in the two tires can cause their diameters to differ enough to result in this kind of problem. "A difference of 15 psi inflation may result in the less inflated tire supporting 500 pounds less than the tire with the inflation. A similar action occurs when one tire's diameter is smaller than its mate. A difference of 1/4" in diameter may result in the larger tire carrying 600 pounds more than the smaller. The shift in load becomes more prevalent as the difference in diameters or inflation becomes greater" (Retread). "By properly matching duals, you will greatly reduce the probability of tire problems and will find that your worn tires are more retreadable" (retread.org).

Hidden tire wear expenses are not the only problem from underinflated tires.

They're just the beginning.

A truck tire goes through a full revolution, flexing all the way around, about 500 times per mile. At 60 miles per hour — a mile a minute — that's 500 times a minute. Tire engineers call this flexing "deflection." Tires are designed to withstand a certain amount of deflection during their lifespan.

Underinflation, though, increases deflection, which means underinflated tires consume more energy, which uses up more fuel.

How much more?

Underinflation by 10% can reduce fuel economy by .5 to 1%, according to the EPA.

| Percent Under-Inflated | Loss of MPG | Additional Gallons of Fuel Burned* | Additional Fuel Cost** |

|---|---|---|---|

| 0% | - | - | - |

| 10% | 1% | 73 | $292 |

| 20% | 2% | 125 | $500 |

| 30% | 3% | 221 | $884 |

*Based on 50,000 miles driven at an avg. of 7 MPG. **Assuming $4.00 gallon of fuel.

Taking these numbers to fleet scale, a 2020 Freightwaves article estimated the USPS had 9500 leased trailers in its fleet. Only considering leased trailers, which could cost USPS $8.3 million in extra fuel a year.

4 steps anyone can take to prevent loss of tire pressure

Here's a reminder of 4 easy, common-sense steps to make sure all your tires are inflated properly.

- Check tire pressure regularly. Use a good gauge, and keep it calibrated.

- Keep wheels clean and properly lubricated.

- Make sure valve stems and cores are in good condition. A valve core must seal at very high pressure. If even a tiny bit of dirt gets in, it can prevent proper sealing. Just as water can freeze and crack concrete, water can freeze inside valve stems, which disrupts the seal.

- Use good quality metal valve caps. Caps are the primary seal against valve leaks and keep dirt and water out of the mechanism.

20 minutes for longer tire life

It only takes 20 minutes to check and adjust the tire pressure on 18 wheels. If you do it every week, chances are you'll experience fewer problems with underinflated tires. That means increased uptime, better fuel efficiency, longer tread life, and improved retread-ability—all of which can keep a slow leak of profit from exiting your bottom line.

Now, go check that tire pressure.