6 Simple Steps to Load Refrigerated Cargo Properly

Transportation is a vital link in the “cold chain” that gets perishable products from farm to fork. For refrigerated haulers, maintaining the proper cargo temperature consistently throughout deliveries is key.

Today’s trailer refrigeration units provide sophisticated capabilities for maintaining proper temperature control, yet even the best refrigeration technology can’t completely assure the safety of cargo that was improperly loaded.

Here are six steps to load refrigerated cargo that can help safeguard it in transit.

1. Chill the Goods

Transport refrigeration units are designed to maintain the temperature of the load, not to change it. Therefore, refrigerated cargo should be at its preferred temperature when it's loaded into the trailer.

In short, if the cargo should be transported at 34˚ F, it should be cooled to 34˚ F prior to loading.

2. Cool the Trailer

The trailer should also be pre-cooled to the proper temperature prior to loading. Pre-cooling is critical, because excess heat in the cargo space or walls could transfer to the cargo and increase its temperature.

3. Keep it Moving!

Ensure cargo doesn’t sit on an unrefrigerated dock for long periods. If it’s allowed to warm up on the loading dock, it can create hot spots in the trailer once it's loaded.

4. Space Out

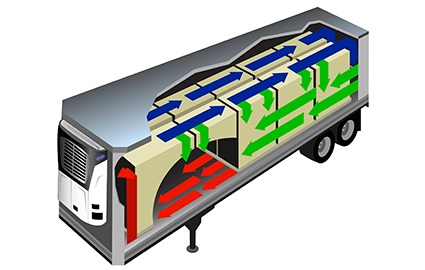

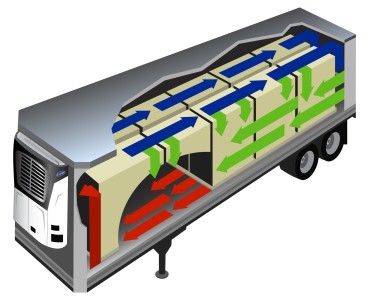

This is how air flows within a refrigerated trailer.

Poor air distribution can be an issue even when refrigeration capacity is more than adequate. Airflow obstructions can cause hot spots and short-cycling of the refrigeration system.

To ensure proper airflow, maintain at least 1-2″ of clearance from trailer sidewalls and at least 9″ of clearance from the ceiling.

At the back end, keep at least 4″ of clearance space between cargo and the rear doors.

And never block the refrigeration system’s evaporator outlet.

5. Go with the Flow

If possible, use an air chute to aid in air distribution. An air chute is a flexible duct made of vinyl, mesh or polyethylene that runs the length of the trailer above the cargo and helps provide uniform air distribution throughout. For single-temperature loads, a channeled “T-rail” floor maintains return airflow underneath cartons. If the floor is flat, cargo should be stacked on pallets, which will allow airflow underneath.

6. Stop When You Drop

During loading and deliveries , the temptation might be to keep running the refrigeration unit, but it’s best to temporarily shut it off.

Shutting down the unit while the doors are open prevents a cascade of effects that can impair refrigeration integrity. For example, when the refrigeration unit is left running, the unit fan can draw in warm, humid air. That air can condense and freeze on the refrigeration unit’s evaporator coil, disrupting airflow and impairing cooling performance. When that occurs, the unit will go into frequent defrost modes, during which it will not provide cooling.

Shutting off the refrigeration system during unloading (and loading) not only helps prevent these consequences, it also reduces fuel consumption, saving diesel for when it’s needed most—on the highway.

Your specific operation could require special loading procedures. You can get more information on the Thermo King and Carrier Transicold websites.

Have you read 4 hot tips to manage cool loads?

Get more information on the refrigerated trailers in the XTRA Lease fleet.